Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: DFC&DFRC-lj-291

Brand: DFC&DFRC

Material: Stone

Shift Type: Infinitely Variable

Fuel: Electric

Control: PLC

Automation: Automatic

Certification: CE

Customized: Customized

Application: Industry

MOQ: 1 Set

Color: Customized

Weight: Depends On Model

Packing: Safety Packing

Delivery Time: Depends On Order Quantity

Production Time: Depends On Order Quantity

Payment Terms: Fob, Exw, Fca

Payment Method: Paypal,t/t,western Union,etc.

Item Name: Acrylic Flame Polisher

Packaging: Safety packing

Productivity: 1-500 pcs per month

Transportation: Ocean,Air

Place of Origin: Suzhou

Supply Ability: 10000PCS IN 3 MONTHS

Certificate: ce

HS Code: 8205510000

Port: Shanghai

Payment Type: T/T,Paypal,Money Gram,Western Union

Incoterm: FOB,EXW,FCA

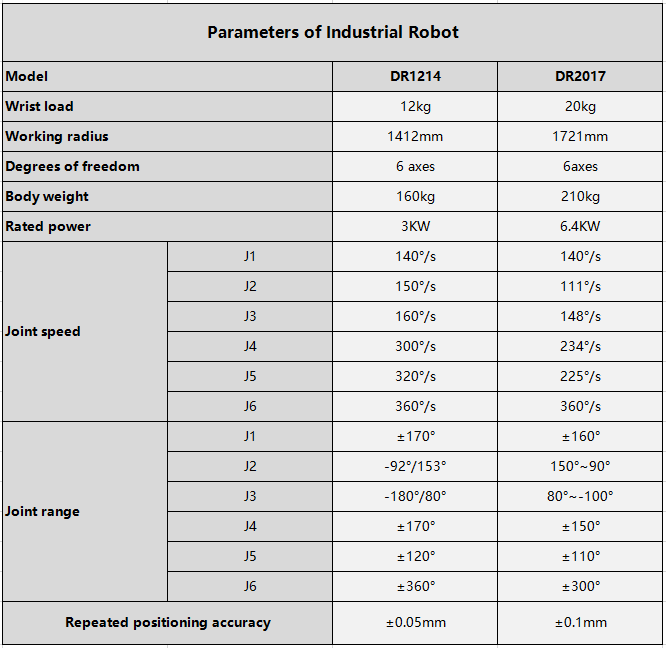

Acrylic workpiece grinding processing needs our flame polisher. Our polisher is different from nowadays market Grinder . Our polisher modular includes our Force Control System, or active contact flange, or you can call it constant force actuator. It can keep the pressure imposing onto the workpiece in a setted range, so that the workpiece surface grinding effect can be even and consistent. sandpaper replacement device is not a necessary equipment for the whole grinding system, but for some high requirement and high production efficiency, it is very essential. Acrylic active contact flange is an application of our grinding force control system, grinding active contact flange, or Grinding Constant Force Actuator.

Product Categories : Grinder Sander Polisher > Polisher

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.